Engineering Efficiency: How Controlled Air is Pioneering Sustainable Innovation

https://youtu.be/C3Rel1fbo34?si=J91K--tdytuLUnI2 In today’s world, sustainability is no longer just an option; it’s a necessity. Controlled Air has long been a leader in delivering full-service energy solutions to clients across the New England area, bringing expertise in designing and engineering advanced energy systems – including gas heat pumps (GHPs), co-generation combined...

Future ready building solutions

Future-Ready Building Solutions: Meeting Energy and Comfort Goals in a Changing World The Controlled Air sales team held a webinar for our customers focusing on potential upgrades and the future of energy efficient technology. In case you missed it, you can watch the full webinar below.

Southington YMCA

SOUTHINGTON YMCA Controlled Air installed a Yanmar cogeneration system in coordination with a new boiler plant and domestic hot water production to reduce energy costs for the Southington YMCA. Our work included the mechanical demolition and removal of existing oil tanks, boilers, domestic hot water tanks, and remaining equipment from the previous co-generation system. At...

Pomperaug High School

Pomperaug High School has been a long time customer of Controlled Air Inc. We have had many projects over the years. We currently have two large projects in process. One is the pool room complete renovations and the second is updating the heating for the gym. Details will be coming...

Ethel Walker School

Ethel Walker School is located in Connecticut on a 175-acre campus sits amidst farms and meadows. For more than 100 years, The Ethel Walker School has been an all-girls school for grades 6-12 plus postgraduate education. This past summer Controlled Air, Inc. Worked with A.P. Construction to provide the HVAC...

Friends Center for Children

Controlled Air, Inc. is thrilled to be part of this wonderful project alongside O, R & L Construction. Friends Center for Children provides much needed early childcare and education for kids 3 months to 5 years, year-round. They aim offer a safe affordable place for children while also paying teachers a livable wages....

HVAC Refrigeration Updates in 2024

Refrigeration Requirements The EPA and federal government has implemented the next round of refrigeration requirements, and outlined those for the next 2 decades. In previous years, R22 was phased out, in the next phase of the process R410A will be reduced and then discontinued altogether. As a Controlled Air customer, we...

Closed Circuit Cooler Replacement

Controlled Air, Inc. recently replaced an Evapco Cooler with an Evapco closed circuit cooler. The new Evapco cooler has low fan sound, an easy-to-maintain drive system, and a swing-out motor. We also installed a new VFD one-source power control panel with an integral variable frequency fan drive. Additionally, the steel...

HIPOWER Stand-by Generators

ABOUT HIPOWER SYSTEMS HIPOWER SYSTEMS (a division of Himoinsa, S.L.; a member of the YANMAR Co. Ltd group of companies) is the principal supplier of power distribution and prime, stand alone power-generation equipment and packages to the U.S. and Canadian markets, serving the Residential, Commercial and Industrial sectors including the...

Tax Credit Available on Yanmar Gas Heat Pumps Ends in 2024

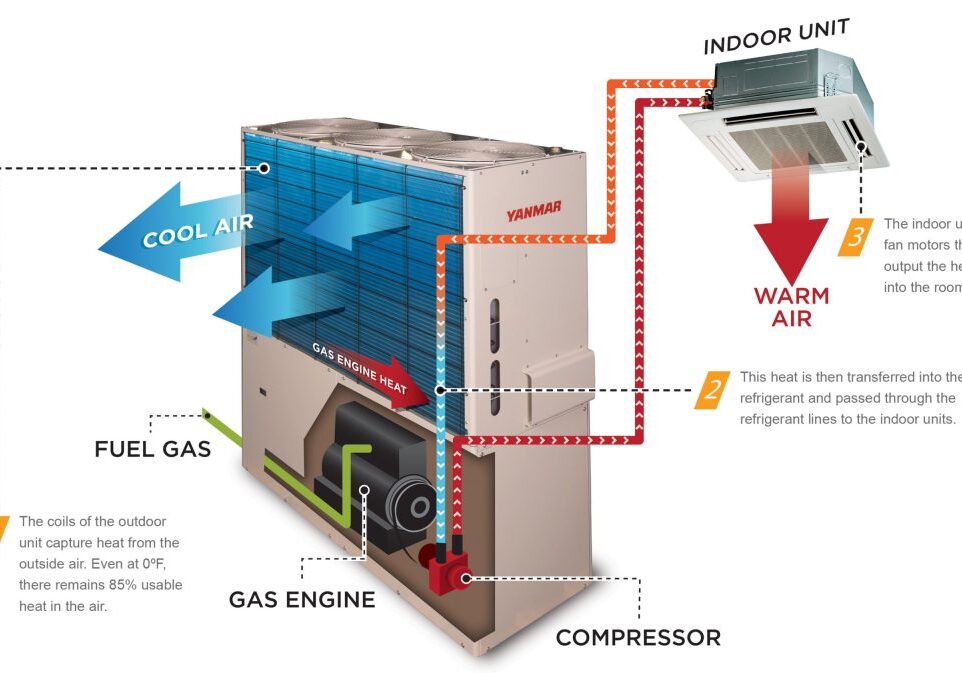

We want to remind everyone that the Gas Heat Pump (GHP) systems manufactured by Yanmar qualify for the 30% tax credit, as well as for direct payments to tax-exempt entities, under the Inflation Reduction Act (IRA). This tax benefit only applies to systems installed by December 31, 2024. Due to...

Energy Efficient Financing Available

Controlled Air is now an approved contractor of the National Energy Improvement Fund. The National Energy Improvement Fund (NEIF) is a mission-based lender offering financing for improvements that make businesses resilient and energy efficient. The financing is available to businesses, non-profits, and municipalities. Controlled Air chose NEIF to work with,...

LiveWell

Controlled Air is part of a 50 million expansion at Dementia-focused LiveWell in the Plantsville section of Southington. LiveWell is a not-for-profit care provider that is solely focused on providing services for people with Alzheimer's disease and dementia. Its 8-acre campus features nursing, assisted living, and adult day facilities. The...

Tax Credits Available on Gas Heat Pumps

We are excited to share that we have confirmed the Gas Heat Pump (GHP) systems manufactured by Yanmar qualifies for the 30% tax credit, as well as for direct payments to tax exempt entities, under the Inflation Reduction Act (IRA). Yanmar GHP is considered a mechanical cogeneration product and should...

International Women in Engineering Day

How or why did you choose engineering as a career path/area of study? Math and science were always my best subjects. In Highschool I took one CAD class my freshman year and loved it and my CAD teacher encouraged me to sign up for all his CAD and tech ed...

Middletown Recreation Center

The Middletown Recreation Center had is soft grand opening on Monday, January 9th. In this recent update, Controlled Air worked with Clarke Energy to create a energy efficient solution integrating multiple products including YANMAR CHP. More information will be provided soon.

Controlled Air Gains 40 years of sales & engineering experience with appointment of Michael P. Patton

Controlled Air, Inc., a division of Yanmar America, is pleased to announce that Michael Patton is joining its sales team as a Design-Build Sales Engineer. For more than 25 years, Michael has been a technical sales leader in the environmental, energy, and water industry. This builds on his more than...

The Elm City Bioscience Center

Controlled Air Inc. provided mechanical design build support to the Elm City Bioscience building infrastructure upgrades located in New Haven. The bioscience building is 113,620 sq ft which includes 8 stories plus a lower level and mechanical penthouse. The project will be on-going with multiple floors being converted from smaller...

Controlled Air, Inc. becomes Yanmar America’s center for engineering excellence and service solutions after acquisition by Yanmar

Controlled Air, Inc. becomes Yanmar America’s center for engineering excellence and service solutions after acquisition by Yanmar. Branford, CT (October 3, 2022) - Yanmar America has signed a definitive agreement to acquire Controlled Air Inc., a privately owned, premier HVAC solutions provider in Connecticut. For over a century, YANMAR has...

Naugatuck High School

A recent article in Combined Heat and Power Magazine highlighted an energy project at Naugatuck High School. Controlled Air Inc. worked with Advanced Energy Efficiencies to develop a cogeneration installation that will provide 140 kW of electrical power and 820,000 Btus of hot water supply. Advanced Energy Efficiencies put together...

Fascia’s Chocolate

Fascia's Chocolates is a family owned chocolate company located in Waterbury CT. They have been in existence since 1964 and have been winners of multiple awards. As they have grown and their energy demands have increased they decided to make improvements to their existing facility. Advanced Energy Efficiencies and Controlled...