ECO-FRIENDLY, COST-EFFECTIVE POWER AND HEAT

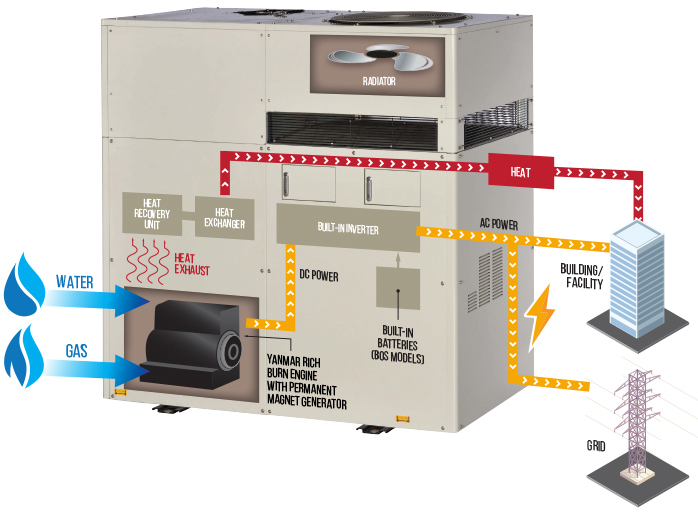

Cogeneration, also known as Combined Heat and Power (CHP), is an innovative solution that generates both electricity and heat from a single fuel source, such as natural gas or propane, onsite at the point of use. CHP eliminates the distribution losses that occur when energy is transmitted over power lines. It recovers otherwise wasted heat for use within your building, offering a truly sustainable and reliable energy solution.

Cogeneration systems are ideal for commercial and industrial buildings where both high amounts of eletricity and hot water are needed, providing electricity, heating, and hot water simultaneously. Advanced models, known as trigeneration systems, go a step further by adding cooling capabilities. These systems capture the heat generated during high-temperature combustion, which is then used for hot water and space heating.

Cogeneration systems offer the quickest ROI of any other energy saving option.

CHP in Action

Conventional water heaters are often wasteful because fuel burning at temperatures greater than 2500°F produces only low-grade energy — hot water at 150°F to 200°F. With systems that burn natural gas or propane to heat water, this can mean excessive energy consumption, particularly when combined with buying electricity from a utility.

Controlled Air, Inc. can help design a more cost-efficient system using cogeneration Modules.

Through cogeneration, high-temperature combustion produces both hot water and valuable electric power. Thermal performance is comparable to conventional water heaters, but in addition, 26% of the fuel's energy is converted into high-grade electrical energy for a combined electrical and heating efficiency of 83%. The fuel's energy potential, both high-grade and low-grade, is maximized.

Green Building Benefits

Compared to conventional boilers and water heaters that waste excess energy, cogeneration systems deliver significant cost savings while reducing your carbon footprint.

Whether you're looking to enhance your energy independence, lower your energy costs, or contribute to a greener future, cogeneration systems are the perfect choice for creating a more efficient and sustainable facility.

Cogeneration systems:

- Are cost-effective, highly reliable, easy to maintain, compact and quiet.

- Are more efficient than traditional centralized power plants and on-site gas use.

- Offsets boiler or other heating equipment usage with waste heat recovery.

- Easily integrate into various electrical and thermal systems, including new construction or existing facilities.

- Offer the fastest ROI of any energy saving options, and the more power you use, the quicker the ROI.

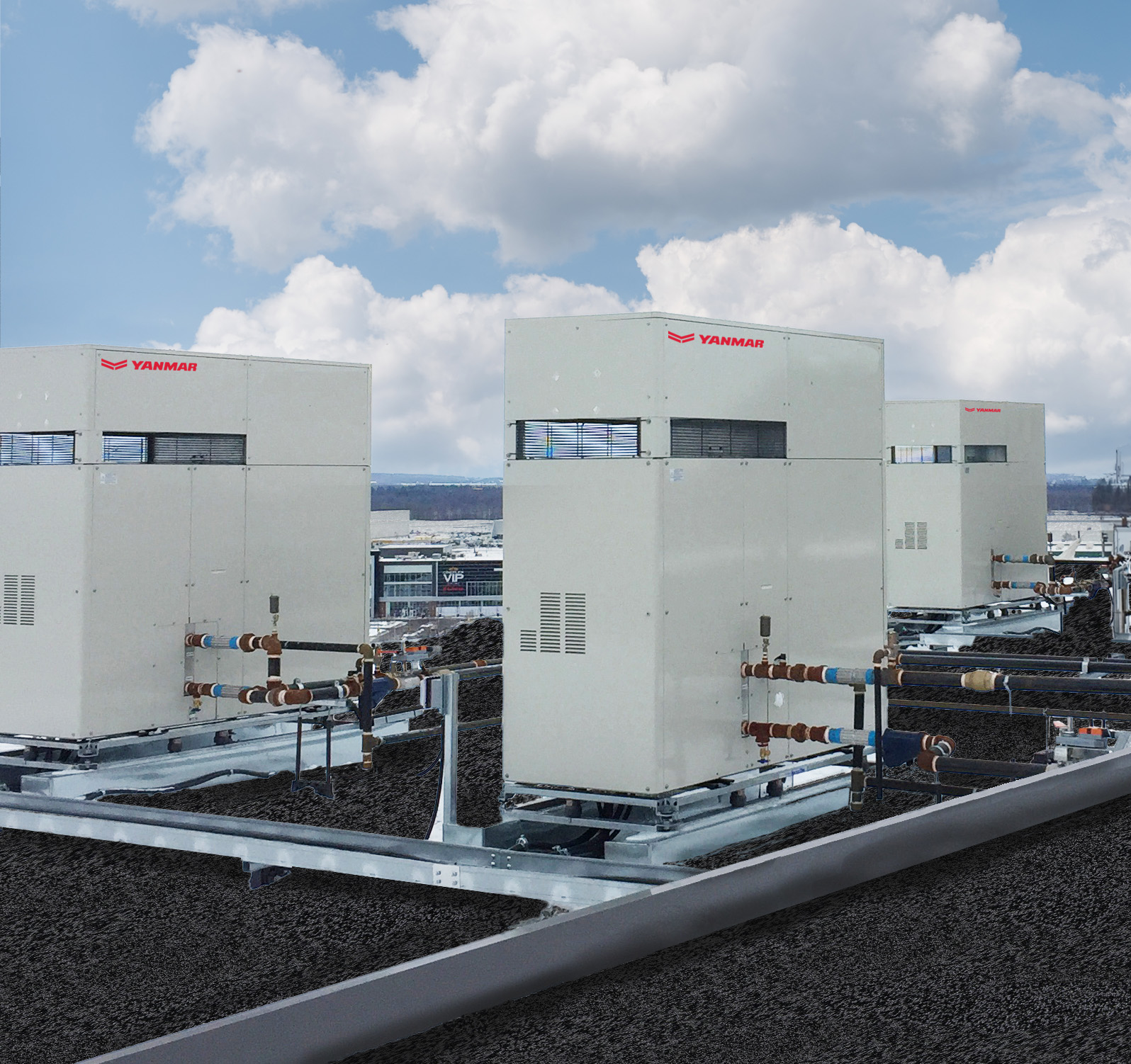

Commercial and Industrial Applications

Controlled Air, Inc. can provide cogeneration units ranging in size from 30 kW to 650 kW for:

Hospitals & healthcare facilities

Schools, colleges & universities

Hotels, motels, multi-unit residential

Sports & rec centers, swimming pools

Offices, commercial, food & beverage

Cities, government & municipal

See Controlled Air’s completed projects

CHP QUICK CHECK

Estimated chp sizing based on your building type and estimated energy usage.