EFFICIENCY & QUALITY FROM THE SUSTAINABILITY EXPERTS

Get high-quality solutions and innovation from the team that specializes in solving complex commercial facility challenges. We help you make sense of drastically changing technology by assessing your current needs, evaluating your current infrastructure and recommending the best solutions to serve you now and into the future.

Design Build

Controlled Air specialists can design environmental and sustainable energy systems for any building or complex. Energy-efficient heating and cooling units and co-generation systems are our specialty.

We’ll start with a walkthrough of your facility and a discussion of your needs. Our expert engineers will then work within your goals and growth plans and apply our technical knowledge to your unique requirements. Using our HAP program, we’ll create solution options for you to choose from. We’re familiar with all codes for various facilities including laboratories, cleanrooms, and more.

Plan & Spec

Provide us the plans from your engineer or architect and Controlled Air’s Plan & Spec team can work within your existing engineering specifications. We will recommend the highest quality, most cost-effective products, systems and installation methods.

We also provide step-by-step project management, assuring that your installation is accomplished on schedule and comes in on budget.

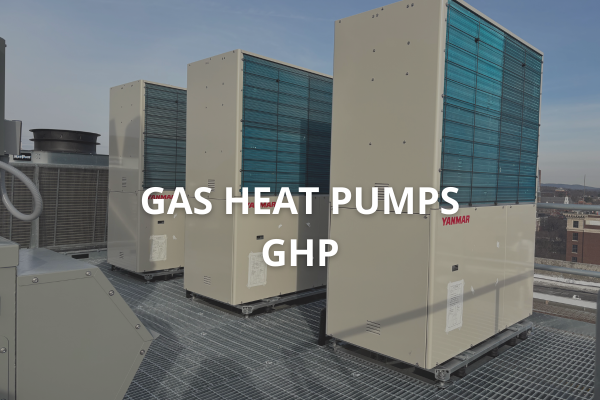

Equipment Replacement

Controlled Air can recommend and install the best replacements for your old equipment including ducted and ductless splits, rooftop units and boilers. We’ll assess your current system performance and

help you navigate the challenges of replacements, including structural modifications for safely installing today’s heavier, larger units, meeting modern building codes and ventilation requirements and phasing out old technology.

We help you make sense of long-term sustainability, Total Costs of Ownership, warranties, and planning for minimal disruption during downtime.

Ready to find out more?

Contact us to find out more about our services and find out how Controlled Air, Inc. can help your facility become more energy efficient.

Engineering

Controlled Air’s engineers have unmatched expertise and experience with every kind of building environment and facility management challenge. Here are some examples that show how our engineering process ensures we develop the best plan for your facility.

HAP Program

- Uses ASHRAE Heat Balance load method.

- Permits hourly and seasonal scheduling of occupancy, internal heat gains, and fan and thermostat operation.

- Models one 24-hour cooling design day for each month using ASHRAE recommended design weather data and clear sky solar radiation procedures.

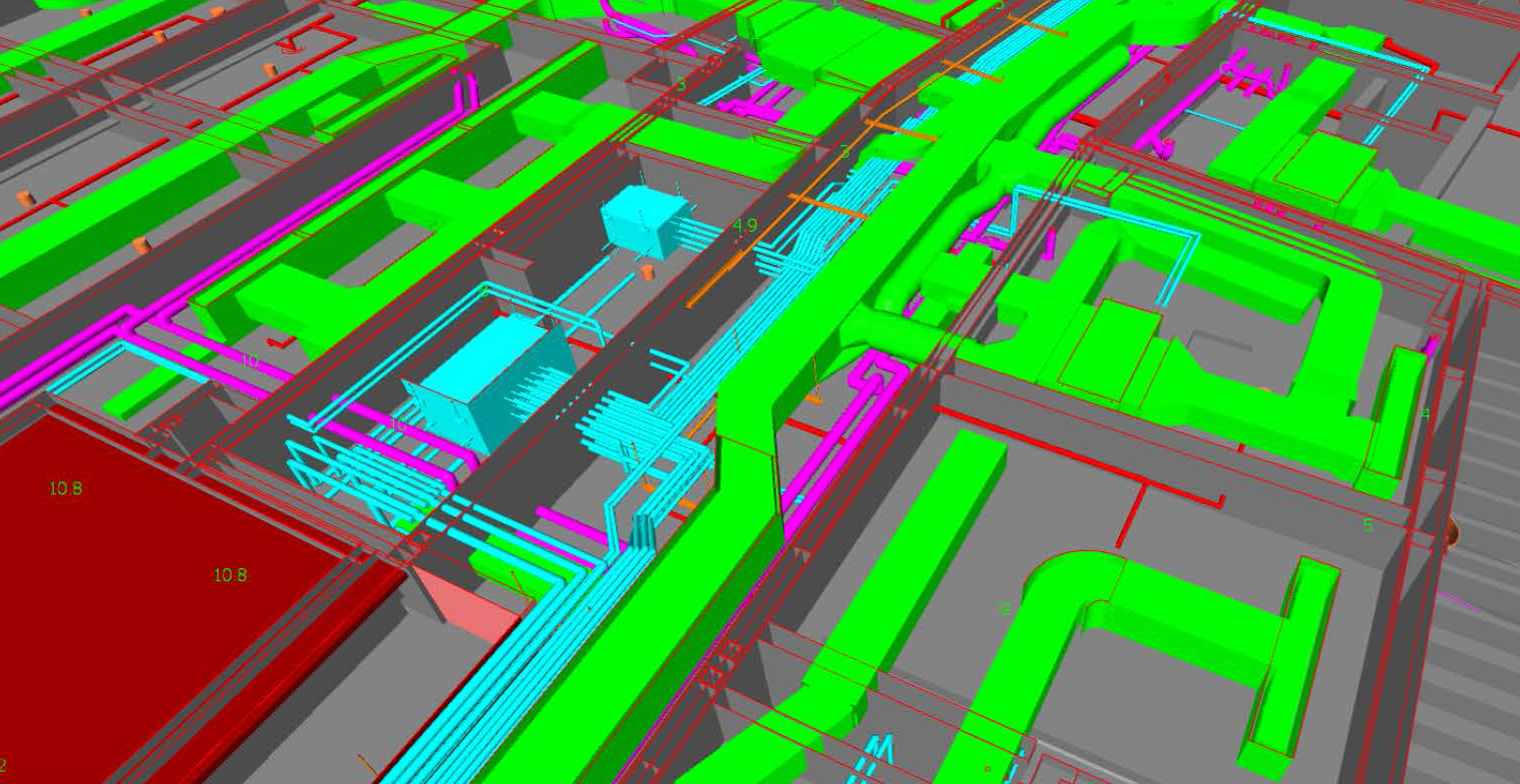

Coordination & 3D Modeling Estimating Software

- Provides up-to-date information on the cost of material and labor.

- Builds historical data to provide a competitive proposal.

- Creates a model visualization that provides clarity and understanding for all involved.

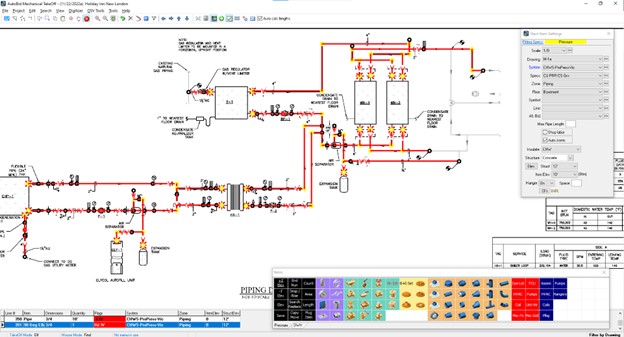

Load Calculations & Energy Analysis

- Models shapes, structures, and systems in 3D with parametric accuracy, precision, and ease.

- Empowers multidisciplinary teams with specialty toolsets and a unified project environment.

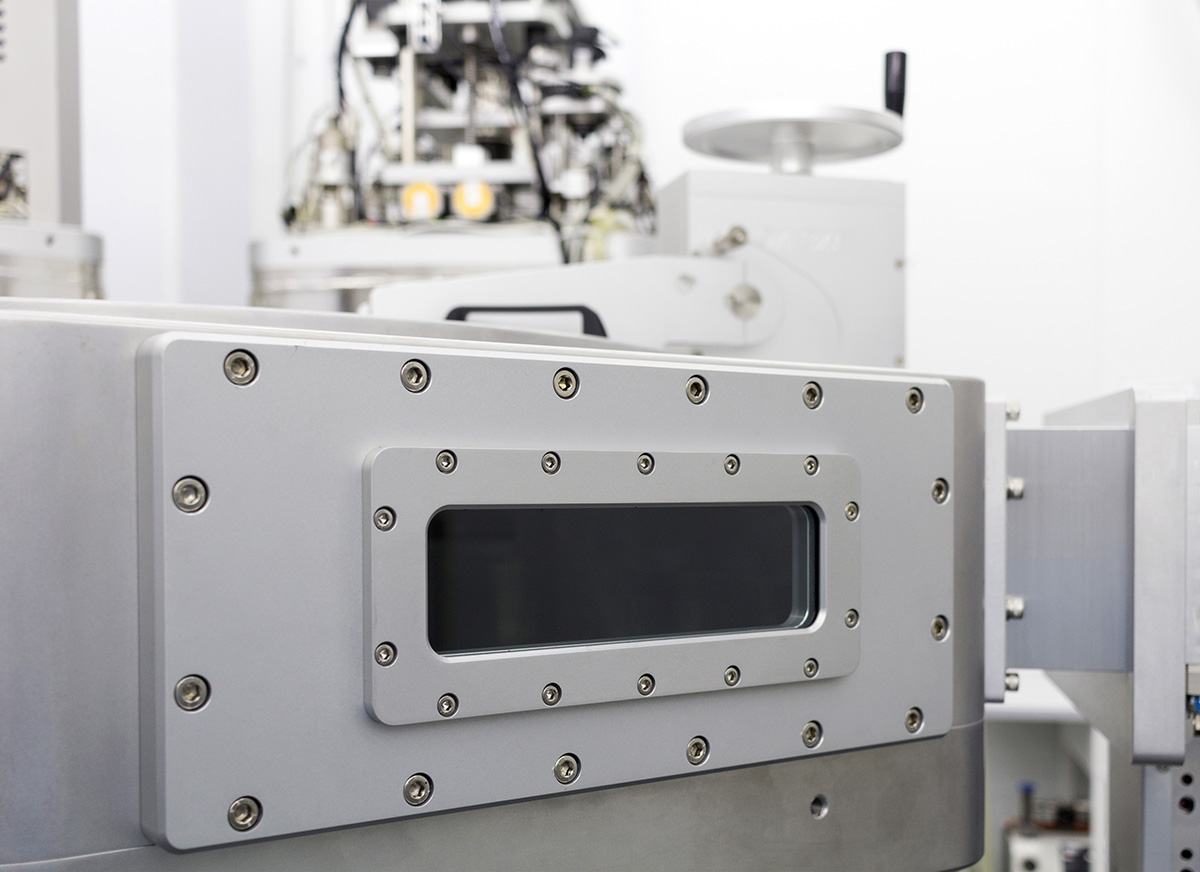

Cleanrooms

We are specialists in creating custom Cleanrooms for critical applications such as laboratories, pharmaceutical companies and electronics manufacturing. Our Cleanrooms have specialized filtration and air exchange systems and range from class 1 to class 100,000 depending on your need.

Most Cleanrooms typically maintain a 70 degree temperature with a constant humidity, although we have designed and created specialty Cleanrooms which maintained a constant 40 degrees. We always follow the strictest of government guidelines and often follow even stricter requirements based on customer needs.

Environmental Chambers

Controlled Air can create environmental chambers of any size that simulate all climatic conditions, including high temperature/high humidity jungle conditions, high temperature/low humidity desert conditions and low temperature frigid conditions. These chambers can also be created to clean room tolerances. We also have designed and built drying rooms and tunnels for various process applications.

For more information on a custom environmental chamber, contact us.

Process Heating, Cooling & Humidity Control

We are specialists in creating custom installations to meet our customers’ requirements for special air handling and process cooling needs. We have designed low humidity rooms, data centers, process chillers for cooling and heating molds for manufacturing, steam boilers for mechanicals, sterilizers, clean rooms, operating rooms, jungle rooms and desert dry rooms. Our installations have included chillers, boilers, steam and hot water for all manufacturing processes and data centers.

Contact us If you would like to talk to one of our experts about a custom solution.