Pharmaceutical Laboratory Controls

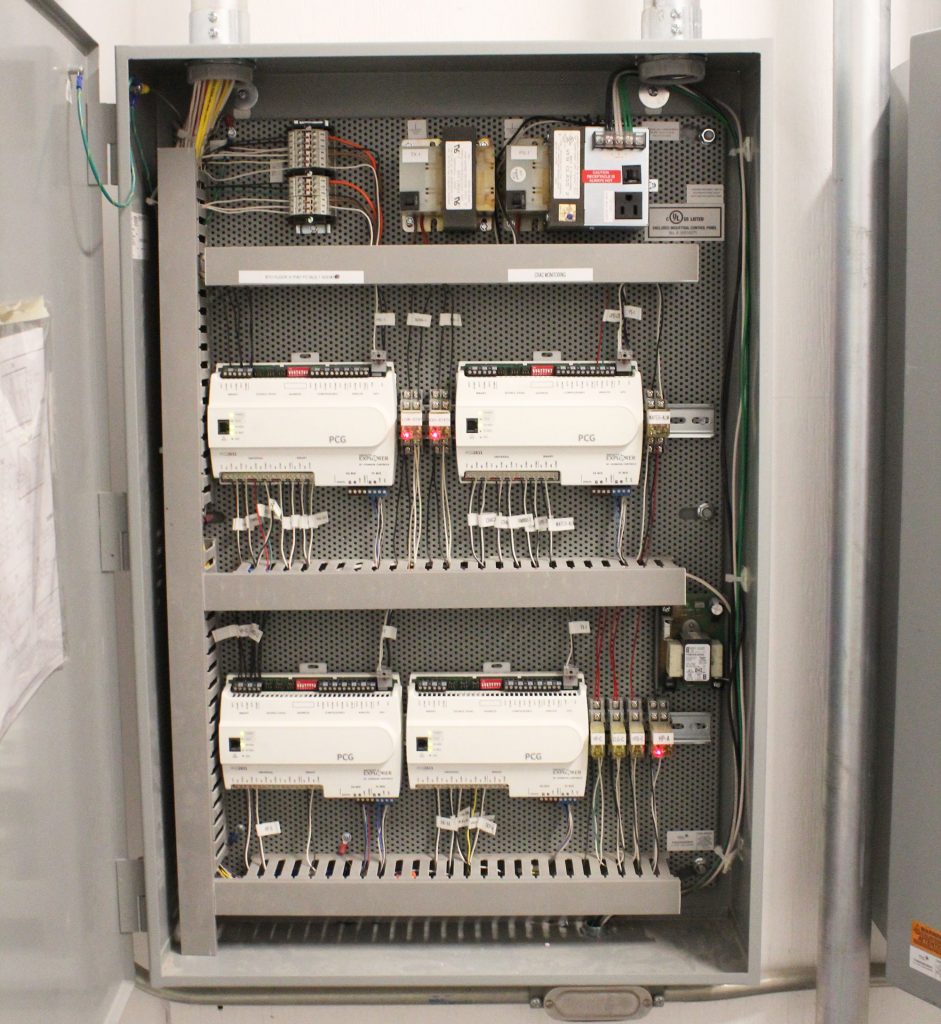

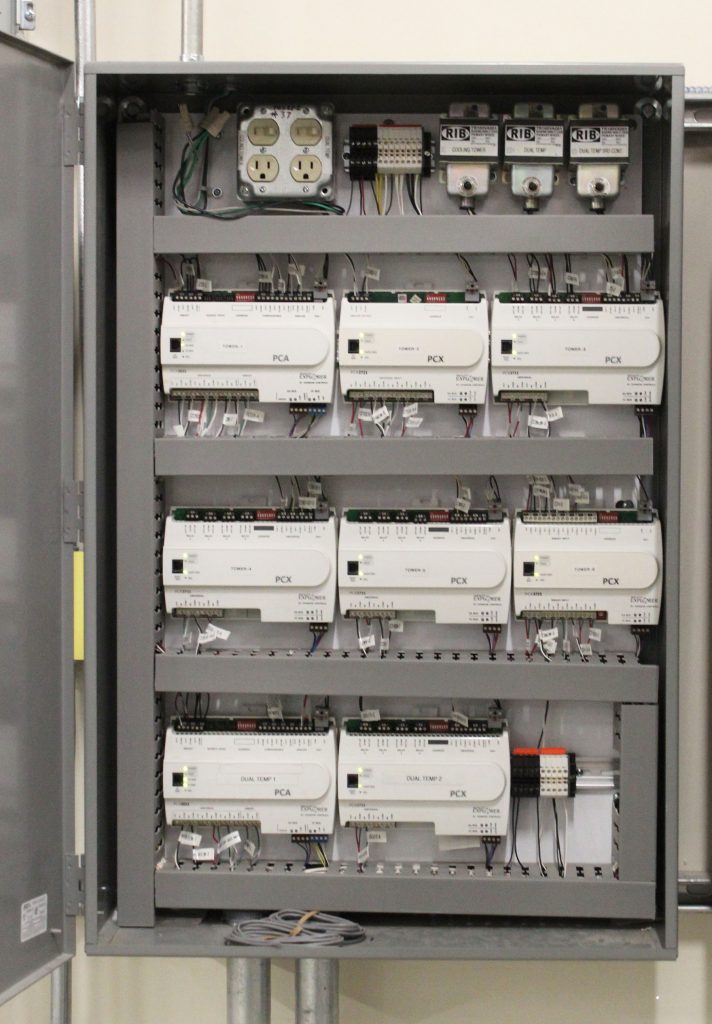

Controlled Air, Inc. installed a Building Control System (BMS) for a pharmaceutical laboratory and office building allowing for proper operation and sequencing. The BMS was integrated with installed mechanical and process equipment. The BMS monitors the electric and BTU usage and work to make equipment operate at peak efficiency. The BMS is made by Johnson Controls by their Facility Explorer line that allows for remote monitoring and alarming if any issues arise. What makes this system more complex than most is the use of data sharing between all systems to make sure all equipment runs optimally. There are spaces within the building that require critical temperature and humidity controls in order to operations to run smoothly.

Below is a list of some of the equipment the BMS also monitors and controls:

- Steam boilers for the lab and domestic hot water.

- Life safety and tenant generator systems supply back up power in the event of power failure for critical areas.

- Kitchen exhaust fans for occupancy, allowing the fans and exhaust hoods only to run when the space is occupied and in use.

- Cooling tower controls, which provides temperature controlled water to the chillers, and heat exchangers serving individual floor air conditioning units.

- Refrigerant monitoring to control exhaust in case of a leak.

- Individual floor air conditioning units, while also controlling occupancy. The individual units serve VAV’s throughout all floors, to maintain individual space temperatures.

- Stairwell pressurization fan control in the case of a fire.

- Boilers serving the entire buildings heating requirements, including baseboard heat, air handling heating coils and zone reheats throughout the space.

Our Specialties

Service & Maintenance Contracts

Cogeneration & Microgrids

Surgical & Medical Facilities

Industrial & Manufacturing